| Air Pillow / Air Cushion Film Automatic Air Filling Machine | |

| Model No. | CQX-12 |

| Shell | ABS |

| Voltage | AC 110 -220V |

| Currenct | 50HZ/60HZ |

| Power | 200 Watt |

| Max Speed | 12 meters/minute |

| Certificate | CE |

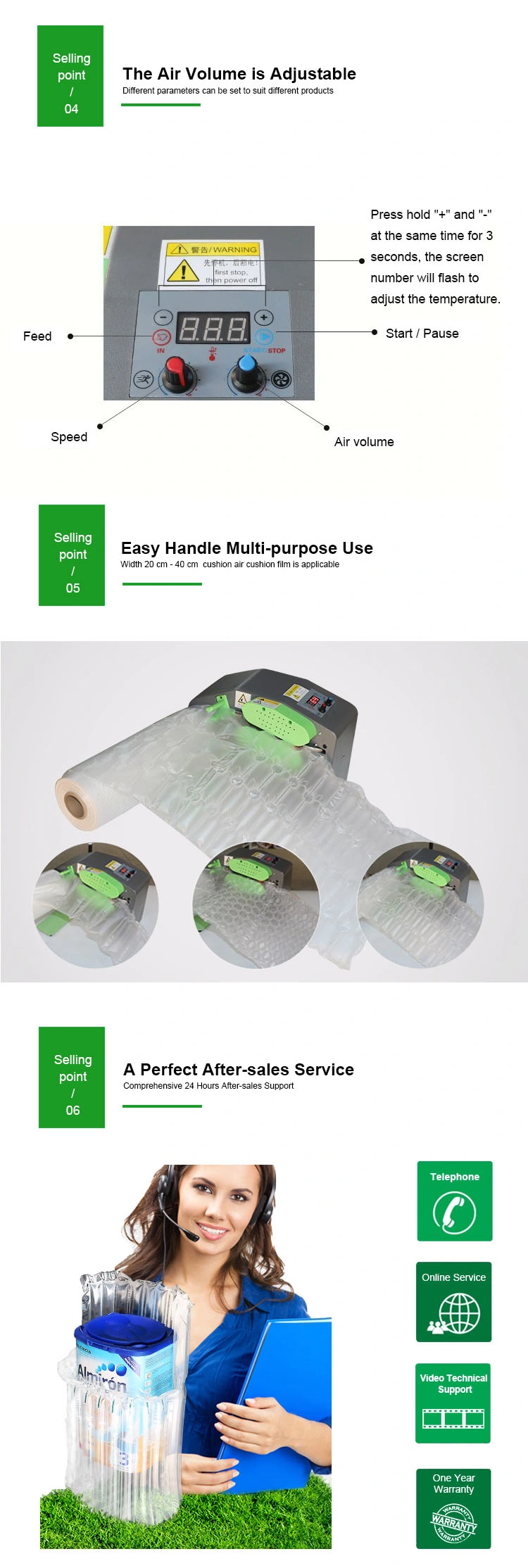

| Application | width 20 - 40 CM film |

| Temperature | 160-220 ºC Adjustable |

| Air volume | Adjustable |

| Warranty | 12 months |

| Dimension | 400MM*145MM*290MM |

| Net weight | 4.95KG |

| Class of insulation | Class I |

CQX-012 Air Filling Machine Operation Manual

Please read the instruction manual carefully, before installing and using the product. (please keeping properly in case of use need)

1. Precautions

In order to ensure the safety of your personal, equipment and property, Please read this manual carefully before installing, operating, maintaining and inspecting CQX-012 Air Filling Machine.

Do not insulated parts inside the machine, touch may cause electric shock.

Do not use it as a life safe device.

Do not use it as a toy.

Do not use it as pillow.

2.Product Information

CQX-012 is a lightweight, portable and easy operational inflatable device. with exquisite and compact appearance, the weight of CQX-012 is less than 6kg,with simple operation interface, the CQX-012's temperature, air volume and speed can be adjusted according to the different characteristics bag, the fastest speed can be up to 12m/min.It is a cost-effective choice of small factories, warehouses and shops.2.1 Parameter

2.1.1 Basic Parameter

Dimension:400MM*180MM*280MM(L*W*H)

Package Dimension:480MM*270MM*360MM(L*W*H)

Net weight:5.2KG

Weight:6.5KG

2.1.2 Technical Parameters

Model:CQX-012 Input voltage:AC 110/220V

Power:240W Rated frequency:50HZ/60HZ

Heat seal temperature:160-220ºC Power connection:Y

Speed:12m/min MAX Air volume:280L/min MAX

Insulation grade:I

2.2 Safety Information

- Please read this manual before installing, operating, maintaining and inspecting CQX-012 Air Filling Machine.

- The authorized dealer or technicians has provided complete training to the operator.

- The operator has read and understood all the safety signs posted on the device.

- Confirm the air filling machine power part--the power source meet the demand of machine, and use with grounding device.(please refer to 3.5: Power Request)

Warn: Do not open the belt cover. belt cover disassemble should done by authorized technicians and technician trained maintenance personnel.

Warn: Be careful of rolled into the machine! when machine start to work like pull the film,inflate the film or sealing, please keep finger, hair, jewelry, and clothes away from the sealing roller.

Warn: Be careful of scalded, pay attention to the surface of the sealing roller, high temperature sealing line may cause scalded!

3. Inflatable bag should used as packing material only!

4. Please confirm the following matters before maintain and repair equipment:

- Power lock and power-off mark & identification have been done according to the regulation.

- Important Note:CQX-012 air filling machine only can used for our company's film. if use with the film not provided by our company, we have right terminate the maintenance services immediately and stop supply all the raw material and relative use material.

Warn: Please do not open the belt cover except for execute the belt replacement of this manual.

5. Check the equipment regularly to ensure:

- The wires of all parts is not scratched, damaged and broken.

- No debris of film residue in the high temperature belt.

- All control parts and display unit is operating normally.

6. Noise

The maximum running noise of air filling machine is 95 decibels, Please confirm if this value available for the standards of local regulations.

7. Environmental Conditions

- Storage temperature:Machine: 0 - 43ºC;Film:0 - 43ºC

- Operating temperature:Machine 16 - 43ºC;Film:16 - 43ºC

8. Potential risks

Even though most of part of CQX-012 air filling machine equipped with belt cover, still some parts not been covered,please be careful during operation.

9. Safety Facilities(Fig. 1)

2.3 Certification

CQX-012 air filling machine have been certificated by CE.3. Installation and Operation

3.1 Power requirements

Warn: Improper grounding may cause electric shock.Warn: Using with Wring board will be increasing the static electricity . the static electricity may cause operational problem and make the operator feel uncomfortable .

For normal operation , the power of CQX-012 should be 110/220 volts , average current should be 2A , peak current should be 3.5A .

3.2 System Components

Fig. 1(Product Components)

1.Main power switch

The Main power switch located the back of the machine,function to turn on/off the system.

2.Start/Stop switch

(1)Start/Stop button:start/stop machine operation.

(2)IN button:control the function of machine auto-operation

3.Main power cord

Plug the power cord into the appropriate power outlet,more details please refer to 3.5 "Power requirements".

4.Control panel

The button panel:Used to set machine related values

5.The sealing machine

Inside are machine parts.

Warn: Do not open the side cover,we only suggest its opened by our company representative and authorized maintenance personnel.

6.Film shaft

It is used to install the film coil, so that the film coil can be fixed and supported.

- Heating strip

Warn:The roller temperature is very high, be careful of scalded!

Warn:Please careful and do not get rolled into the machine

8.Film roll

Film rolls construct with (separate bag)pin holes film,available inflated and sealed by CQX-012.

3.3 Operation Steps

- Install film shaft in the position shown in Fig. 1 (auxiliary tool: screwdriver);

- Connect the power cable to turn the power on, install the film on the film shaft, after film pass the feed rod and been pulled in the middle of the belt, press the auto-feed button, and after the film pull out of the filling machine, then press the start button for filling air.

1. Do not use in a humid environment.

2. Before operation, please take care of following instruction:

- If the system is not grounding properly ,may cause an electric shock.

- Do not open the protective or examine/repair cover. Only our service personnel or authorized dealer maintenance service personnel can open.

- During operation and loading material, please avoid direct touch to roller from finger, clothes, jewelry and hair.(tie hair up suggested).

3. inflatable bag only suggest used as packing materials,do not use it as float, pillow, or child toy.

4. The cover of CQX-012 is plastic, weight of filling material(film) do not over 5 KG,during material loading, do NOT stress it or leaning.

5. When the material is driven by the machine, static electricity will be generated. The material itself will also have static electricity. The operator cannot wear slippers or not wear shoes. Otherwise, the human body will become a conductor of static electricity, and feel like electric shock.

6. After long time operating the machine, if the film does not run smoothly or get stuck, please replace the blade in time.

7. After long time operating the machine, if appearance the sealing edge is not firm, broken seal edge, please confirm if the temperature proper, if the temperature belt broken, if yes, please replace it in time.

8. Speed and air volume of the air filling machine should adjust mutually, differ film have different parameter, no rated standard, need adjust the record according to the actual condition.

Attention:Do not running the machine without material!!!

3.5 Film Storage

Warn:Please use the film produced by our company,if not so,may cause broken bag problems or influence the effect of the packing bag,and even damage the machine.The temperature of storage should be 0 - 43ºC.the film is supposed to stored in 0 - 43ºC. Exceed/below this range may damage the film.

Please noted, this film should in its operating temperature before using.

The films operating temperature range are 16-43ºC . Please used the film within this temperature range to achieve the best sealing effect.

Warn:For the best sealing effect , please ensure the film reaches the operating temperature before use.

4. Maintenance & Repair

4.1 Preventive maintenance

Warn: Before maintain or repair the CQX-012,please do remember turn off the machine,and plug the Main power cord from the socket.| Maintenance cycle | Detail | description |

| weekly | check&clean | open the belt cover of machine,blow off the dust; check if any abnormal abrasion machine component. |

| every month | contact | Arrange an on-site inspection; Contact the authorized distributor or our technical service representative to check the machine. |

Fig. 4 (blade replacement and installation instruction diagram)

Use the screwdriver loosen the 3 screws at the root of the tube,(refer to Fig. 3), take the tube out, loosen the blade and fix the screws, change the blade(refer to Fig. 4), then install the tube back.

4.3 Replace the Teflon belt

Fig. 5 (Teflon belt replacement and installation instruction diagram A)

Fig. 6 (Teflon belt replacement and installation instruction diagram B)

Use the screwdriver remove the belt cover,push the heating strip to the direction of traction wheel(to make the belt loose),After belt been loose,then remove the belt ,replace the new belt and install the belt cover back.

4.4 Replace the Teflon adhesive tape

Fig. 7 (teflon adhesive tape replacement and installation instruction diagram A)

Fig. 7 (Teflon adhesive tape replacement and installation instruction diagram B)

Use the screwdriver remove the belt cover,push the heating strip to the direction of traction wheel(to make the belt loose),After belt been loose,then remove the belt,use screwdriver to loose the screw and gasket,which in the middle of heating strip;then remove the heating strip(noted:springs may slip out),tear the the Teflon adhesive tape and paste a new one,then install the heating strip,belt and belt cover back to the original position in proper order.

4.5 Troubleshooting

LLL:No temperature sensor or sensor fault

H-1:Heating strip abnormal

H-2:Motor abnormal

H-3:Air producer abnormal

H-4:Temperature abnormal

When these error code shows,please contact the authorized distributor or technician to deal with it.

4.6 Accessory and Spare Part List

| Part No. | Description | Quantity | Unit |

| 1 | Blade | 1 | Box |

| 2 | Discharge shaft | 1 | Piece |

| 3 | Power cable | 1 | Piece |

| 4 | Allen wrench | 2 | Pieces |

| 5 | Instructions | 1 | Piece |

| 6 | Teflon belt | 2 | Pieces |

| 7 | Teflon adhesive tape | 4 | Pieces |

Lanxi Shammah New Material Technology Co., Ltd.

32, Chunlan Road, Lanjiang Street, Lanxi, Zhejiang, China (Mainland)

Tel: +86-150-5855-9598 | Fax: +86-579-8388-9011

Website: http://lxshammah.en.made-in-china.com

Website on Alibaba: lxshammah.en.made-in-china.com

Website on Made In China: https://lxshammah.en.made-in-china.com/