Flexible high volume production. Hydraulic press lines are mainly used to manufacture a wide variety of parts in small to medium lot sizes. Depending on the required forming operations, the line typically consists of between four and six single presses. The production process is fully automated from the blank to the finished component. Depending on the requirements, automation is provided by either conventional robots or Crossbar Robots. The control and visualization systems of the hydraulic press lines provide a user-friendly operation environment. They also feature efficient fault diagnostics and clear administration of all the process and die data for presses and automation systems.

Hydraulic press 4 column hydraulic Sheet metal deep drawing

Features

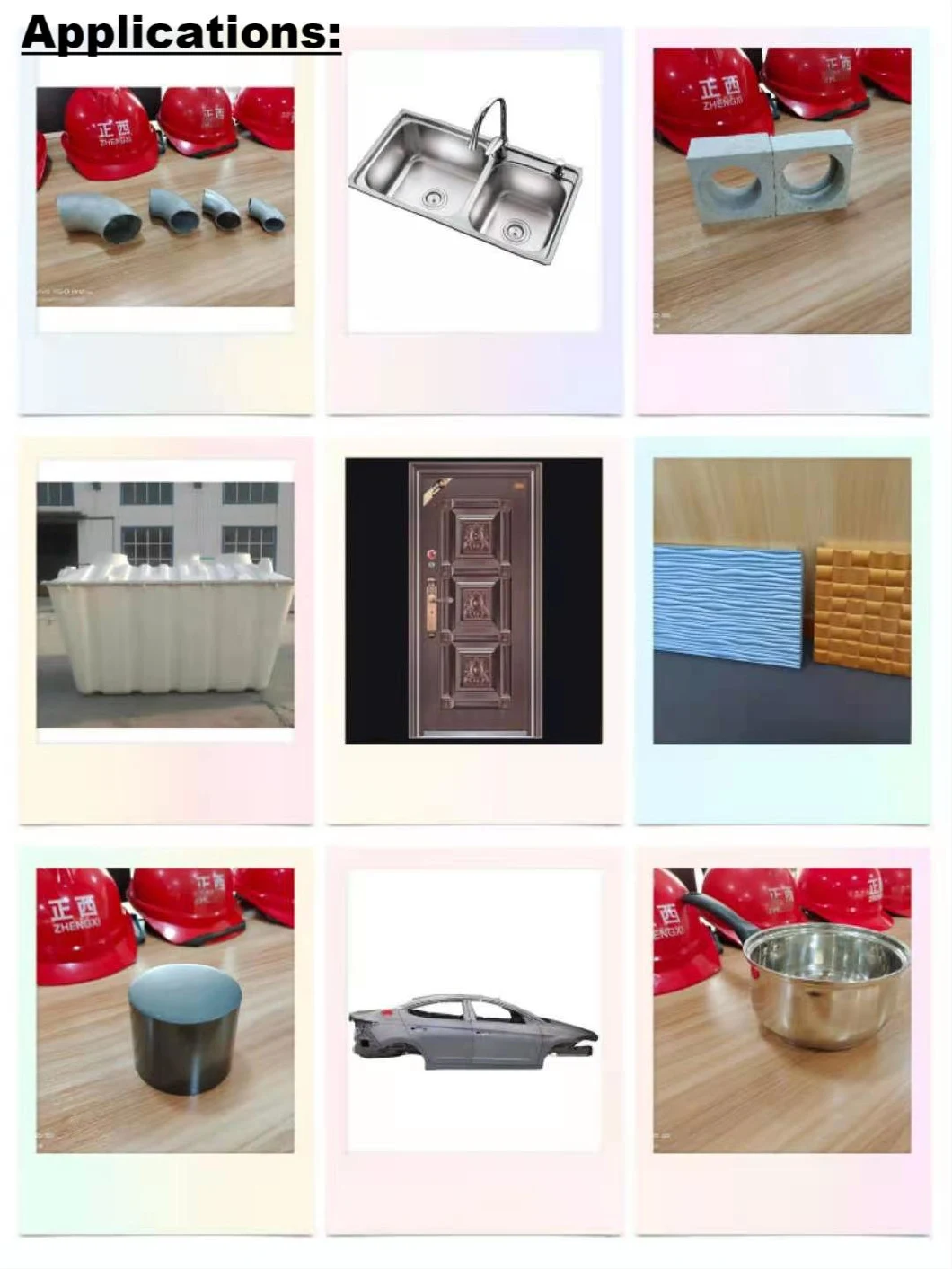

1.Hydraulic machine that used the hydrostatic pressure to process metal, plastic, rubber, wood, powder and other products .

2. It is commonly used in the pressing process and press forming process, such as: forging, stamping, cold extrusion, straightening, bending, flanging, sheet metal deep drawing, powder metallurgy, press-fit etc.

3.Significant technical and economic advantages in reducing weight, reducing the number of parts and the number of molds, improve the stiffness and strength, reduce production costs, etc.

SPECS of Yz33

| Model | unit | Yz33-25T | Yz33-50T | Yz33-63T | Yz33-100T | Yz33-160T | Yz33-250T | |

| Clamping Force | KN | 250 | 500 | 630 | 1000 | 1600 | 2500 | |

| Working layer | Qty | 2~4 | 2~4 | 2~4 | 2~4 | 2~4 | 2~4 | |

| Piston stroke | mm | 180 | 250 | 250 | 250/250 | 250/250 | 500 | |

| Heating Platen daylight | mm | 90 | 125 | 125 | 125 | 125 | 125 | |

| Heating Platen Size | Left-right | mm | 350 | 400 | 500 | 600 | 750 | 900 |

| Front-back | mm | 350 | 400 | 500 | 600 | 850 | 900 | |

| Heating plate power | KW | 1.5 | 2.2 | 3 | 7.5 | 11 | 15 | |

| Motor power | KW | 7.2 | 9 | 10.8 | 33.75 | 45 | 45 | |